The prospective of agro straw and stalk briquette utilizationThe bright and promising market of biomass briquettes and charcoal conforms to the advance of briquetting technology and utilization scale of briquette press and charcoal machine.Biomass briquette press and charcoal machine are two kinds…

Biomass Briquette Machine

From biomass waste into biomass briquettes and charcoalThe available biomass material covers a wide range to be made into biomass briquettes and charcoal, such as sawdust, straw and stalk, rice husk, palm EFB and palm tree, bough and twigs and the like. Almost all plants can be processed with the …

Myanmar Client Ordered Briquette Machine and Carbonizing Furnace

In October 10th, 2015, our Myanmar customer Zaw Win paid the money for the ZBJ-03 briquette machine and THL-06 carbonizing furnace. After using the machines for a period of time, he expressed that he was very satisfied with our machines and their running conditions. We will establish a l…

The advantages for you to start a biomass briquette making and charcoal manufacturing production line

The advantages for you to start a biomass briquette making and charcoal manufacturing production lineThe investment in a briquette making machine and charcoal production line depends upon the wide use of biomass briquette fuel and charcoal, therefore, the marketing of the low-carbon and …

KMEC-The Reliable manufacturer of Pini Kay Briquette Machines

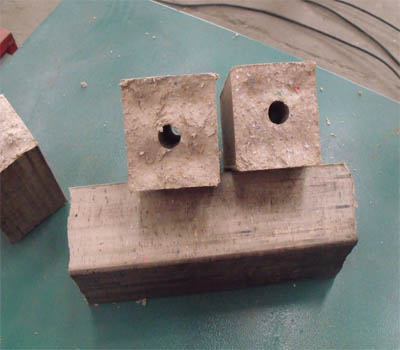

Pini kay Briquette machines are capable of processing biomass briquettes with super high density and compression. Moreover, the Pini Kay briquettes are characterized by high surface baking technology, which protects briquette per se against excessive moisture. Therefore Pini kay is generally appli…

The value of straw and stalk briquette machine

The value of straw and stalk briquette machine Briquette machine The briquette machine, good at handling agro straw and stalk, is a newly designed biomass energy processing facility, featuring low costs and high margins. The price of biomass briquettes produced from the machine is favorably …

Biomass Briquettes Made From Crushed Carton

Biomass briquettes are made from agricultural waste and are a replacement for fossil fuel such as oil or coal, and can be sued to heat boiler in manufacturing plants, and also have application in developing countries. Biomass briquettes are a renewable source of energy and avoid fossil carbon to t…

Briquette and charcoal fuel to release the Crimean crisis, Ukraine

As a country rich in forest and wood resource, Ukraine does have a solid and lavish foundation for biomass briquette and charcoal production since wood briquette plants demand continuous input of biomass material such as sawdust, saw shavings, wood chips and other biomass forms. Biomass materia…

Methods of solving heavy moisture of raw material

Raining and heavy frog often causes high moisture of raw material when we use the biomass processing equipment. It would affect the quality of Charcoal / Biomass briquette seriously. We must pay attention to moisture and dry the material one more time. Then what we should do during the production …

Development of straw briquette press machine in China

As briquetting equipment, straw briquette press machine extrude high density fuel chip from smashed straw and package again. The result of biomass fuel boiler is taking the place of normal coal stove is that the traditional using pattern of coal stove cause the air pollution. Meanwhile, biomass fu…