Charcoal is a desirable fuel because it produces a hot, long-lasting, virtually smokeless fire. Combined with other materials and formed into uniform chunks called briquettes, it is popular used for outdoor cooking in the United States. Basic charcoal is produced by burning a carbon-rich material …

Raw materials for biomass briquette

Raw material of Biomass briquette Human has used energy for a long history. In 19th century, coal is the most important energy. As the development of industrial, people begin to realize the disadvantages of coal fuel. It has big pollution to the air and the resources are less and less. Under this…

Development of biomass briquetting technology

Briquettes are ready to substitute of lignite/coal/wood in industrial boiler and brick kiln for the thermal application. Biomass briquettes are non-conventional source of energy, eco-friendly, renewable in nature, non polluting and economical. It’s made through binder less technique without use of…

How to maintain the biomass briquette machine

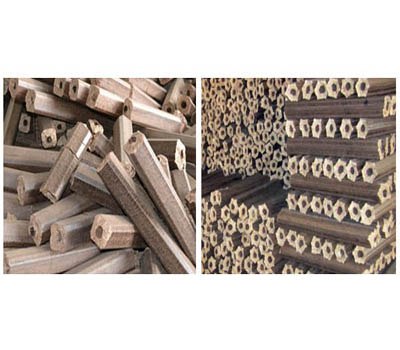

Biomass densification is the bonding together of waste biomass product, such as wood chips or sawdust, peanut husk, rice husk, sunflower seed husks, bagasse (sugar cane or sugar beet residue), coffee shells, coconut husks, etc. The bonding is achieved by the pressure and heat of the biomass brique…

Briquette Making Machines Can Rescue Forests from Depletion

In Tanzania, Japan volunteers is supplying briquettes making machine countrywide at subsidized prices in order to control the ongoing tons of destruction of forests, basically used a major source of household fuel. In the near future, the problem maybe controlled effectively. The government tak…

Characteristics of Biomass briquetting and Their Significance

In order to produce good quality briquettes, feed preparation is very important. Feed parameters are discussed in this section, as these play a practicable role in biomass technology.For biomass briquetting, it is important to know the feed parameters that influence the extrusion process. For diff…

Companies develop new biomass briquette presses

There are two companies develop a kind of new biomass briquette presses. They are Pennsylvania-based BHS Energy LLC and California-based Biomass Briquette Systems LLC. Each announced the availability of new biomass briquette presses in December.BHS Energy has developed a small-scale briquette pres…

Effect of species, particle size and compacting pressure on briquette making machine

Densification of biomass waste materials has provided a great boost to the utilization of wood and agricultural waste for domestic and industrial fuel. However, the processes involved in the production of this fuel make it more expensive than fossil fuel. This is because densification of wood wast…

Biofuel briquette machine

Biofuel is a kind of new renewable fuel, it mainly produced from the biomass material. Solid biofuel is a wide field and includes woody biomass (chips, firewood, wood pellets, briquettes), herbaceous biomass (straw, grass, miscanthus etc, fruit biomass (olive stones, cherry pits, grape waste, nut …

How to improve the briquetting performance

A productive biomass briquetting process could make high quality briquette for fuel with high efficiency. Of course, a high quality briquette press is a good start to briquetting solution. But, it’s a complicated process for biomass briquetting. To get success of briquetting, you have to have a go…