There is a huge current and growing demand to fond alternative clean energy sources that meet new legislation requirements to reduce emissions from fossil fuels. Agro Waste as sources of energy in India shows great potential. The process of briquetting is the physical transformation of loose raw m…

Impact of spices of raw material to the cracks of biomass briquette

Sawdust has the best briquetting performance, and after the sawdust, it is corn straw and cotton straw, the worst effect of briquetting is the processing wood wastes. According to estimation, the worst for processing is the residues of decorations, it has big difference with pure sawdust which is …

Failure analysis of briquette machine

Biomass is an environment friendly, clean, cheap and versatile fuel. Biomass produced from organic compound such as agriculture residues (husk, cob, stalks, leaves, stems, shells, sticks). Also waste from bio-product industries like sawmills, plywood industries, furniture like sawmills, plywood in…

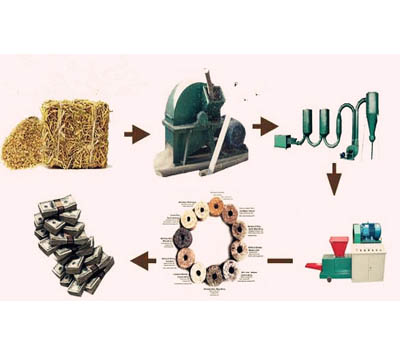

Making Fuel Briquettes from Biomass

Biomass now has become a main source for making renewable energy. It can be made into methane, biogas, charcoal, liquefied fuel or other solid fuel. While the most popular and widely applied way is to make biomass into fuel briquettes. Biomass briquettes are solid biofuel pressed from sawdust, …

Three factors for the success of briquetting

The test has shown that there are three factors which affect the briquetting process–they are dryness of raw material, the appropriate propeller and the proper temperature for briquetting. 1. The moisture content of raw material. The briquette machine has high standard to the moisture co…

Briquetting machine in China

Following with the development of economic, more and more people come to realize the importance of air pollution and carbon emission. People’s healthy and living condition greatly concerned with the air condition. In china, we comes through the unexpected bad whether condition ever before, everyon…

How to reduce mechanic wearing of briquette machine

The wear resistance of briquette machine is closely related to the spindle and forming part. The bearing in the spindle as well as the roller and the roller sheet in the forming part are the wearing parts of the briquette machine. Its wearing resistance performance directly affects the service lif…

Making Briquettes by Hydraulic Briquetting Machine

Introduction Briquette machine is also called briquette press machine. This hydraulic briquette machine can briquetting all kinds of wood wastes, straw stalk, straw residues, wasted clothes, wasted papers, wasted plastics and other wood or biomass wastes to large masses. Finished briquettes are…

Temperature control of briquette machine

Today, demanding is always changing, and the briquette press is a kind of necessary equipment for charcoal industry. It has been loved by many enterprises and it plays an important role during the charcoal compaction industry which has close relationship with people’s life. Briquette machin…

Air blast dryer and rotary dryer

Now, there are mainly two types of dryer which are widely used in the briquetting process. They are air blast dryer and rotary dryer. Next, we would like to introduce them separately. The clients can chose the proper type of machine according to the different features, prices of machine and differ…