In the production process of mechanism charcoal, briquetting plays a vital role. While in the process of briquetting, due to the effect of high temperature and friction, the service life of the propeller is usually short. Propeller of good quality can be used for 7-10 days, while the poor one can …

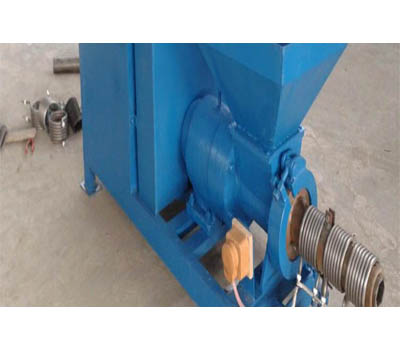

Detailed description of briquette machine

Briquette machine is the core equipment among the charcoal machine equipment, it is indispensable for the production of biomass briquettes. In addition, the briquette machine also takes the core technology of charcoal machine. Other equipment, like the crusher, drying machine, carbonization furnac…

The molding principle and conditions of briquette machine

Briquette machine is the special equipment used for processing sawdust, straw, grass, wild weeds and other materials into briquettes by mechanical extrusion and compression in order to make the combustion value and time of per unit volume increased and prolonged by several times. The briquettes pr…

Does temperature influence the quality of briquette produced by biomass briquette machine

When using biomass briquette machine to produce mechanism charcoal, temperature is the problem that always exists in the whole producing process, which is also closely related to the production of machine-made charcoal. If you want to produce high quality mechanism charcoal, the process of drying,…

How to replace the heating ring of wood briquette machine

In the production process of mechanism charcoal, making briquettes with wood briquette machine is a critical part. In order to promote the softening and combination of of lignin and improve the compactness and hardness of the briquettes, the heating ring is used in wood briquette machine. In the m…

The density of briquette produced by briquette machine

The briquette machine is a kind of indispensable equipment for charcoal industry. It has been widely praised and accepted by many enterprises and plays an important role during the charcoal compaction industry. The briquettes produced by briquette machine are also widely used in many countries aro…

Analysis of the briquette fracture and spark in the production of biomass briquette machine

When we use the biomass briquette machine to produce biomass briquette, sometimes the briquette produced may break and even lead to the crash of biomass briquette machine that can not work normally. Since restart of the biomass briquette machine is quite troublesome, so how to quickly find out the…

The importance of quick wear parts in briquette machine

The quick wear parts of briquette machine include the screw propeller, heating ring, taper sleeve and sleeve. A set of high quality quick wear parts can ensure smooth operation and high efficiency of briquette machine. The internal forming part of briquette machine produced by our company is made …

The molding technology of briquette machine determines its trend of development

As we know, the mechanism charcoal is produced through molding, grinding, drying, carbonization and other processes, among which briquette machine is often used for molding. Briquette machine is the special equipment for molding sawdust, rice husks, peanut shells and straw after crushing. No addit…

Installation guide of briquette machine

Briquette machine is the most important molding equipment in the process of making charcoal. The principle briquette machine adopts is physical extrusion. Biomass pellet contains the component called “lignin”, which would become liquid at high temperatures and separated out from the particles. It …