In the production process of briquettes and mechanical charcoal, the procedure of raw material forming has higher technology content, which is one of the most complicated parts of the mechanical charcoal production. The following is a detailed description of the structure of biomass briquetti…

What determines the burning time in the production of charcoal

Longer burning time of charcoal produced by briquette machine and carbonizing furnace marks the better quality. Only charcoal with longer burning time is more popular with the market, which can also promote the rapid development of charcoal machine equipment. But in the actual production…

What inspection should be made before running charcoal briquette machine

Equipment used in the production of charcoal are mainly composed of four parts: the crusher, dryer, biomass briquetting plant for sale and carbonizing furnace. When these equipment have been assembled into a complete production line, customers need to make a careful inspection for the cr…

Elimination methods for large or uneven moisture of material in briquette plant for sale

As the production technology of mechanical charcoal is getting mature, a large number of manufacturers with uneven technical levels are emerged in the manufacturing industry of briquette plant for sale. In fact, there are two factors that would affect t…

What failure would occur in the production process of briquette machine?

It is inevitable to face some mechanical problems in the production of any equipment. But in the production process of mechanical charcoal, emergency shutdown of briquette machine is rare. Strictly speaking, suddenly shut down of briquette machine is not going to happen under normal circ…

Features of high quality wood crusher and the matters needing attention when choosing

Wood crusher machine is an essential equipment used in the production of biomass briquettes with briquette machine. When purchasing wood processing machinery, what need to be paid attention to is the quality of the mechanical equipment, then what should be noticed when buying the wood crusher…

How to improve the quality of corn cob charcoal

To improve the quality of the corn cob charcoal in the production of briquette machine and carbonizing furnace, we can not only use high-performance processing equipment and manual operation. In fact, technological improvement on the raw material can also improve the quality of finished …

Security vulnerabilities in the production of briquette machine

In recent years, with the rapid development of tourism industry, the industry development of briquette machine can’t keep up with demand, especially for barbecues in the coastal areas in the summer with larger demand for the mechanical charcoal and the price is higher, which brings…

Machine-made charcoal and activated carbon

Is the charcoal produced by charcoal briquette machine also called activated carbon? In the following content, we would make a detailed description about the production process, the nature and usage of machine made charcoal and activated carbon. Machine made charcoal and activated car…

What are the conditions needed for briquette machine production

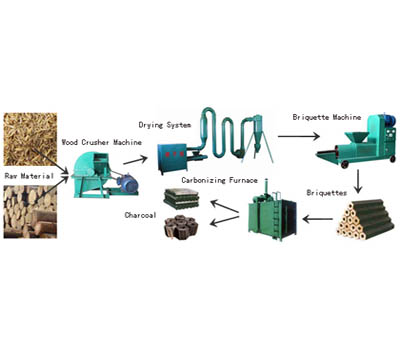

The main equipment used in the production of briquette machine are composed of four parts: the wood crusher machine, dryer, briquette machine and carbonizing furnace. Raw material inspection is an important step before the production of briquette machine. The humidity of straw materials …