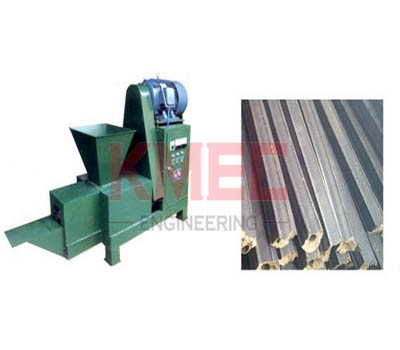

Cause analysis of premature damage of straw briquetting machine bearing

In the process of using straw briquetting machine, sometimes the bearing is damaged prematurely. What’s the matter? There are many reasons for premature damage of straw briquetting machine bearings, the main reasons include: not filling lubricant or lubricating oil in time; Or the lubricant is not filled in place; Or improper lubricant selection; Incorrect lubrication and so on. So what are the reasons for the early damage of the bearing of straw briquetting machine?

Premature damage of straw briquetting machine bearing is mainly affected by the following four factors:

1. Improper installation. The installation is not in place, the installation is biased or not installed in the bearing position, resulting in too small bearing clearance. The inner and outer rings are not in the same center of rotation, resulting in different centers; When installing, brute force is used, and hitting the bearing directly with a hammer is the most harmful to the bearing; Is the main cause of deformation. Suggestion: Choose appropriate or professional installation tools for the bearing of straw briquetting machine, and use special instruments for inspection after installation.

2. Poor lubrication is also one of the main reasons for premature damage of bearings. The main reasons include: not filling lubricant or lubricating oil in time; Or the lubricant is not filled in place; Or improper lubricant selection; Incorrect lubrication and so on. Suggestion: Select the correct lubricant or lubricating oil and use the correct lubrication filling method.

3. Pollution will also lead to premature damage of the bearing of straw briquetting machine. Pollution refers to dust, metal chips and the like entering the bearing. The main reasons include: opening the bearing package prematurely before use, resulting in pollution; Unclean working environment during installation, resulting in pollution; The working environment of the bearing is not clean, and the working medium is polluted. Suggestion: It is best not to unpack the bearing before use; Keep the installation environment clean during installation, and clean the bearings to be used; Enhanced sealing device of bearing.

4. Fatigue damage is a common damage way of straw briquetting machine bearings. The common causes of fatigue damage may be: long-term overload operation of bearings; Not repaired in time; Improper maintenance; Equipment aging, etc. Suggestion: Choose the appropriate bearing type and replace the fatigue bearing regularly and timely.