From maize stalk and corn cobs into biomass briquette charcoal

Maize stalk and corn cobs can be processed into briquette charcoal as well. Autumn boasts the season of bumper harvest, and at the same time, a large amount of corn stalk and corn cobs will be produced. Matter of fact, the seemingly wasted material can be processed in a recycled manner into maize stalk briquettes and corn cobs briquette charcoal, the thermal value of which will hit 5000kcal, the equivalent of standard coal. After being combusted, the briquette charcoal, chemically speaking, will become plant ash which is used as potash fertilizer. In this special way, the conventional production of burning forest will be converted into green powerhouse for our sustained economic development, hands down.

We would like to share the experience with you because the renewable career deserves us to pay more attention to and take part in it. We have a client who shared his real story about it. His enterprise was established in 2008. Just before that, he conducted a slew of market surveys on the production of biomass briquettes and briquette charcoal. As we know it is quite reasonable to do that, for investment in certain business matters a lot to investors. Not only the issue of overall costs should be taken into consideration, but also profits, assessment of risks, sustainable development potential and market exploration. Eventually indeed, he was attracted to the potential career not only due to the miracle of the energy transformation but also based upon his relevant experience, for he is a farmer. Therefore, he possesses sufficient raw material and he can collect more from others.

Corn cobs and maize stalk used to be burned directly at home for cooking in rural areas, and some of the material is fed as forage for animal husbandry. Even stacks of stalks were piled behind residences posing a threat to human safety in case of fire hazards. 2008 witnessed his start the briquette charcoal business on a small scale in the very beginning. His sweat at last was rewarded with a success in the investment. He claimed he from the career hit pay dirt. The next year saw another batch of investment in expanding workshop and purchase of another ten briquette presses. Along with the expansion of production scale, yield efficiency was enhanced impressively and the professional skills of operators accumulated as well.

In 2010, crop planting cooperation protocol was set down and carried out between neighboring farmers and him. He noted that the consensus was made not only in favor of himself but also of other innovative farmers and businessmen. The region where they dwell in since then became a model of sustainable development as well.

The fifth year of his briquette and charcoal business hit a new high. What’s worth mentioning is that the scope of raw material is enlarged as well, including wheat straw, peanut shell, cotton stalk and tree branches and twigs.

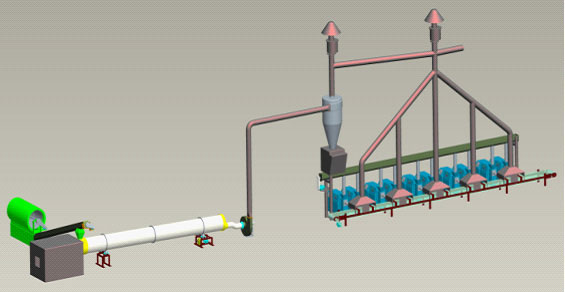

Biomass solid fuel like briquettes and charcoal can be made from agro residue such as stalk and straw, sawdust, bagasse and rice bran, he said, the process of crushing, mixing, drying, squeezing and carbonizing will turn biomass waste into renewable biofuel. Other developed countries such as Danmark, Germany, Belgium, the US and Japan have realized industrial production. A synergized and organic industrial chain together with biofuel boiler, stove and fireplace and power plant has come into being. Therefore, we cannot lag behind and miss out on the promising opportunities, he added.