It is very important to control the moisture of raw materials of straw briquetting machine

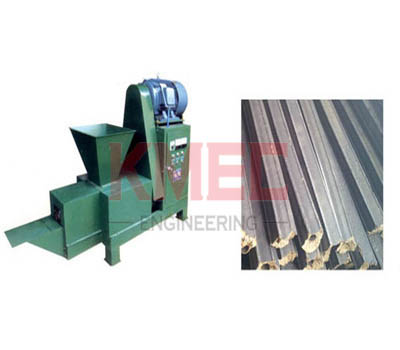

Straw briquettes is a block product made of various straw raw materials by straw briquetting machine. The moisture content of straw briquetting products is closely related to the raw materials. When the moisture content of raw materials exceeds the standard, the current processing technology of straw briquetting machine can’t solve it. Therefore, in order to control the moisture content of straw briquetting products, ensure the final moisture content of products to reach the expected goal, and produce qualified straw briquetting products, we have to start with controlling the moisture content of straw raw materials.

The points to control the moisture of raw materials of straw briquetting machine are as follow:

First of all, the straw briquetting machine must have a perfect raw material management system.

Strictly control the raw material purchasing and warehousing, and the moisture content of conventional raw materials should not exceed the normal index. Anyone who does not meet the requirements is not allowed to purchase or warehousing.

Second, pay attention to the warehouse management of straw briquetting machine.

The warehouse should be ventilated regularly, and generally equipped with temperature and humidity control devices. Raw materials should be delivered out of the warehouse in accordance with the principle of “first in, first out”, so as to ensure that the moisture content and other quality indicators of the delivered raw materials are within the specified fluctuation range. The raw materials should be fed in a limited amount according to the normal production conditions, and the stock period of raw materials should be shortened as far as possible.

Third, the raw materials that are easy to absorb water should not be stacked against the wall, and should not be pressed into warehouses as far as possible.

Appropriate storage time should be set according to the varieties of raw materials, and the moisture content should be re-measured if the storage time exceeds.

Appropriate moisture content can transmit pressure, and can also act as a lubricant, helping particles to fill and embed with each other, thus promoting the molding of raw materials. Too high or too low moisture content is not conducive to compression molding. Different molding methods have different requirements for the moisture content of raw materials. Generally, the moisture content of crop straw is less than 15%. If the moisture content of raw materials is too high, drying equipment can be used for drying treatment first. In short, in order to produce qualified briquette products, the moisture control of straw briquette raw materials must be given absolute attention.