Straw briquetting machine has great development advantages

Now it is the golden autumn season, all kinds of crops are maturing one after another, and the fields are showing a bumper harvest. After the harvest, the treatment of crop straw is also a big problem that puzzles the majority of farmers. The emergence of straw briquetting machine has helped farmers solve this problem. Straw briquetting machine presses corn and other straws and grasses into high-density products, which is not only an ideal way to develop and utilize straw resources, but also has important economic, ecological and social benefits for increasing farmers’ income and sustainable development of agriculture.

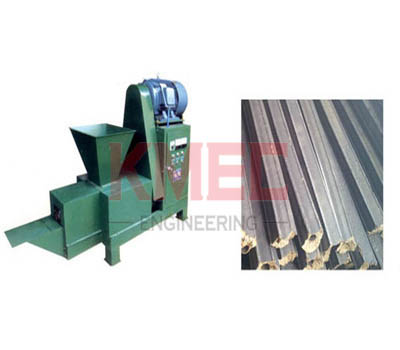

Straw briquetting machine has the advantages of high automation, high output, low price, low power consumption and simple operation. If there is no power equipment, diesel engine can be used instead. Straw briquetting machine is easy to operate and convenient to use: it has high automation degree and less labor, and can be fed manually or automatically by conveyor. Automatic adjustment function of pressing wheel of straw briquetting machine: the pressure angle is automatically adjusted by using the principle of bidirectional rotation of thrust bearing, so that the materials will not be crowded or stuffy, and the stability of discharging and molding will be ensured. Straw briquetting machine has strong material adaptability: it is suitable for the molding of all kinds of biomass raw materials. Straw briquetting machine can process and shape straw from powder to 50mm in length.

Straw briquetting machine has great development advantages:

1. The straw briquetting machine is convenient to produce, and only need two people to operate manually in a production line. It is configured in a fully automatic mode, which can save manpower and fully realize fully automatic production. Moreover, the equipment occupies a small area, and the produced fuel has small smoke, long flame, long burning time and wide application range.

2. Straw briquetting machine is energy-saving and environment-friendly, mainly using natural straw, rice husk, branches, tree stems, sawdust, sawdust, straw, etc. as raw materials. No additives are added in the production process, and the produced “straw coal” will not contain sulfur dioxide, phosphides, carbides and other components.

3. Straw briquette fuel is convenient to use. It can be directly ignited, with high density, high calorific value, fierce firepower and long burning time. It replaces non-renewable resources such as raw coal, liquefied gas and natural gas, and is widely used in various stoves such as domestic stoves, heating stoves, hot water boilers and industrial boilers.

4. Straw briquette fuel is convenient for storage and transportation. It can effectively reduce the space of many straws which are irregular in shape and difficult to be regularized, thus greatly saving the space.

5. After using the straw briquetting machine, we can accurately weigh the weight of these straws, and it is not necessary to accurately estimate and use them as before. Moreover, in the process of straw treatment by using the briquetting machine, not only the shape is changed, but also the briquetting machine will perform some drying treatment on the straw. For some straws with excessive moisture and heavy moisture, it can effectively remove the moisture and play a greater role in the burning process.

6. Straw briquette fuel is widely used, and there is no requirement for stoves. It is a good fuel for farmers, small traders, restaurants, enterprises and institutions, potters’ firing, brick and tile factories, smelting and chemical plants, especially for bio-power plants.

With the concept of protecting the environment and sustainable development gradually being deeply rooted in people’s hearts, the continuous improvement of straw briquetting machine technology, and the government’s comprehensive measures such as increasing financial input and formulating preferential policies, the application prospect of straw briquetting machine will be very broad!