Ball Press Machine-JY

Static pressure ball pressing machineIt is widely used to press easily forming mealy material such as coal dust, middings, coke powder, coking coal, carbon dust, charcoal dust, bamboo charcoal powde…

Product introduction

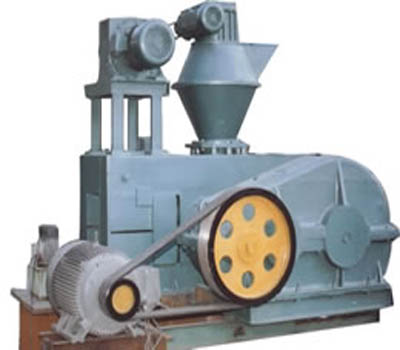

Static pressure ball pressing machine

It is widely used to press easily forming mealy material such as coal dust, middings, coke powder, coking coal, carbon dust, charcoal dust, bamboo charcoal powder, coke dust and shisha charcoal.

Binding agent as one of pivotal auxiliary materials matters in briquetting and it will toughen up hardness and strength of pressed material. Kingman is capable of offering various binding agents and combustion improvers for free to clients.

The working principle of the static ball pressing machine goes: driven by V-belt and reducer, the main shaft and exposed gear can ensure the synchronized running of the two rollers at uniform speed but reverse rotating directions. System pressure will be kept constant via the oil hydraulic circuit, control valve and energy accumulator. After dosed in the surge bin, material will be conveyed to the feeding hopper on which adjustable flashboard is available to keep feeding consistent and material intake even to the forming zone. After the aligned pressure between the two rollers, compacted material will be extruded out smoothly.

The mold

Main technical parameters:

| Model | Roller Dia. (mm) | Yield(t/h) | Power (kw) | Briquette size |

| JY290 | 290 | 2 | 5.5 | As per clients’ requests |

| JY360 | 360 | 4 | 7.5 | As per clients’ requests |

| JY450 | 450 | 6 | 13 | As per clients’ requests |

| JY500 | 500 | 7 | 22 | As per clients’ requests |

| JY650 | 650 | 8 | 30 | As per clients’ requests |

| JY850 | 850 | 9-10 | 45 | As per clients’ requests |

| JY1000 | 1000 | 11-15 | 75 | As per clients’ requests |