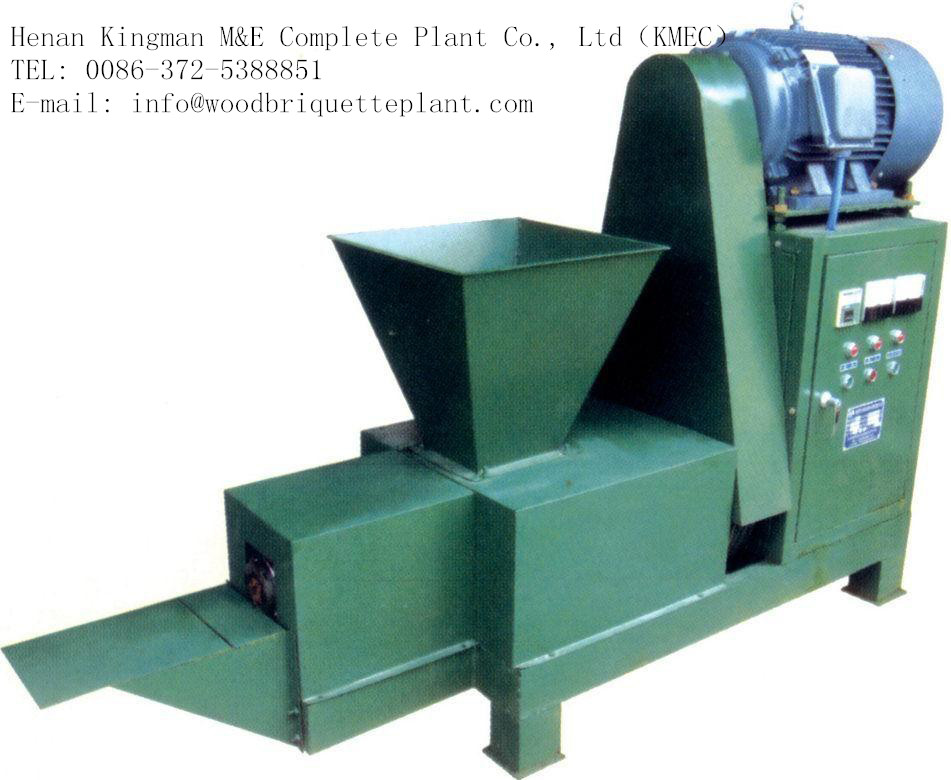

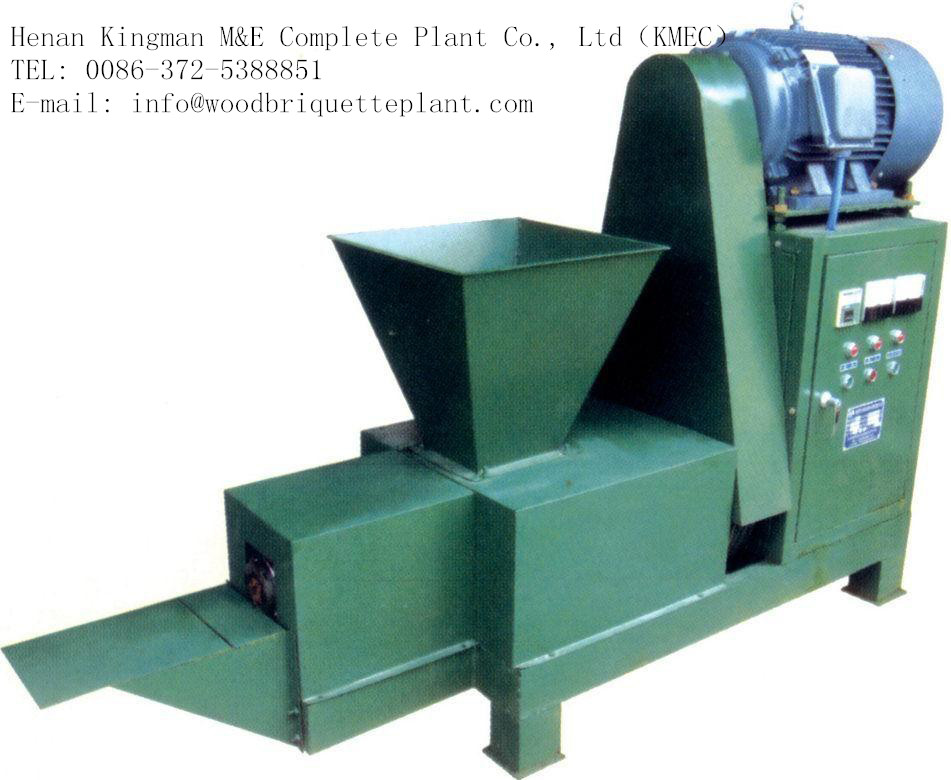

ZBJ-YK Briquette Machines

Briquette Presses-YK

Basic info:

After drying system, material can possess an appropriate moisture content to be processed into briquettes.

Optional mould (also called the die)

Briquette Presses offered by KINGMAN(KMEC) cover a wide range of moulds, namely, according to different requirements for briquette forms, we can provide you with a variety of dies to produce round, square and polygon shapes. But technically, the square shape is more commonly used in terms of extruding force and tolerance clearance between the die and the sleeve.

Consistent quality

The screw spindle is made from alloy steel of high hardness. And gaps between two neighboring spiral petals are equidistant, besides, each angle of the screw shall be the same.

Good product

Thanks to the water jet cutting system, the surface of final products will be produced as smoothly as that of the inner forming sleeve.

Environment-friendly

An exhaust emission system is also needed to keep the workshop from pollution consistently.

Practical economic value

Low maintenance cost will be the marked feature and added value.

Parameter table:

Note: the warranty period lasts 12 months.

Attention:

If material after being crushed and dried has been suitable for the next step briquetting, there is still certain importance which shall be attached to.

1.The Briquette Presses shall be fixed on a flat foundation.

2.During the process of briquetting, temperature should be adjusted according to extruding situation. The electrical heater covers a wide scope of temperature for your reference. Different raw materials demand distinguished temperatures.

--------------------------------------------------------------------------------------------------------------------------------------------

Check out related products herewith:

Mechanically Stamping Briquette Machine Hydraulic Briquette Machine

Basic info:

After drying system, material can possess an appropriate moisture content to be processed into briquettes.

Optional mould (also called the die)

Briquette Presses offered by KINGMAN(KMEC) cover a wide range of moulds, namely, according to different requirements for briquette forms, we can provide you with a variety of dies to produce round, square and polygon shapes. But technically, the square shape is more commonly used in terms of extruding force and tolerance clearance between the die and the sleeve.

Consistent quality

The screw spindle is made from alloy steel of high hardness. And gaps between two neighboring spiral petals are equidistant, besides, each angle of the screw shall be the same.

Good product

Thanks to the water jet cutting system, the surface of final products will be produced as smoothly as that of the inner forming sleeve.

Environment-friendly

An exhaust emission system is also needed to keep the workshop from pollution consistently.

Practical economic value

Low maintenance cost will be the marked feature and added value.

Parameter table:

| Model | ZBJ-YK1 | ZBJ-YK2 | ZBJ-YK3 | ZBJ-YK4 |

| Yield (kg/h) | 180-210kg/h | 300-350kg/h | 180-210kg/h | 300-350kg/h |

| Motor power (kw) | 15kw | 22kw | 15kw | 18.5kw |

| Electric heater (kw) | 6kw | 9kw | 2.2kw×2 | 2.2kw×2 |

| Briquette dia. (mm) | 50mm | 70mm | 50mm×L480mm | 60mm×L500mm |

| Hole dia. of briquette (mm) | 16mm | 20mm | ||

| Briquette density | 1.3g/cm3 | 1.3g/cm3 | 1.3g/cm3 | 1.3g/cm3 |

| Weight (kg) | 585kg | 1300kg | 700kg | |

| Oversize (mm) | 1700×750×1280 | 1900×880×1620 | 2700×600×1600 | 2000×600×1700 |

| Life of the inner forming unit | 1-2 years | 1-2 years | 1-2 years | 1-2 years |

| Cross section range of briquette | 50mm -80mm | 50mm -80mm | 50mm -80mm | 50mm -80mm |

Attention:

If material after being crushed and dried has been suitable for the next step briquetting, there is still certain importance which shall be attached to.

1.The Briquette Presses shall be fixed on a flat foundation.

2.During the process of briquetting, temperature should be adjusted according to extruding situation. The electrical heater covers a wide scope of temperature for your reference. Different raw materials demand distinguished temperatures.

--------------------------------------------------------------------------------------------------------------------------------------------

Check out related products herewith:

Mechanically Stamping Briquette Machine Hydraulic Briquette Machine

Related Products:

Products

- XP Drum Chipper

- FSJI Crusher

- FSJII Hammer Mill

- HGJ Drying System

- SSJ Series Conveyer

- ZBJ-YK Briquette Machines

- ZBJ-CY Briquette Machines

- ZBJ-YY Hydraulic Briquette Machines

- Packing Machine

- THL Carbonizing Furnace

- BPJ Barking Machine

- Ball Press Machine-MFJF

- Ball Press Machine-TLSG

- Ball Press Machine-GFKF

- Ball Press Machine-TFMTF

- Reinforced Ball Press Machine

- Ball Press Machine-TS

- Ball Press Machine-JY

- Ball Press Machine-GY

English

English  Русский

Русский  Español

Español