Companies develop new biomass briquette presses

There are two companies develop a kind of new biomass briquette presses. They are Pennsylvania-based BHS Energy LLC and California-based Biomass Briquette Systems LLC each announced the availability of new biomass briquette presses in December.

BHS Energy has developed a small-scale briquette press designed to compress switchgrass and other biomass materials such as wood waste. The machine produces round briquettes approximately 1.5 inches in diameter and up to one inch in length. They are roughly the size of a golf ball.

Biomass briquette press is a kind of machine to compress the material into cylinder shape with high density under high pressure and high temperature. The materials should be under a certain degree of moisture content and be powdery statement. Briquetting system is the heart process of the whole process, but it is the most important process. Along with the applying of the charcoal, biomass briquette press may be a great help.

The briquette press can be powered by a tractor's power takeoff or by a three-phase motor. It's compact and can be loaded onto a trailer for mobility. When fed switchgrass, it produces approximately 600 pounds of briquettes per hour. When fed wood, it can produce up to 1,000 pounds of briquettes per hour.

According to the engineer, the biomass briquette press is designed to benefit individual farms and other small-scale entities interested in producing their own heating fuel without the expense of investing in an industrial-scale product. He estimates the product will retail for between $35,000 and $48,000. Commercial production of the press is expected to begin in the summer. The company is taking orders for discounted preproduction machines, which will be used to finalize the design.

Biomass Briquette Systems' new mechanical press, the BP-1500, can produce up to 1,500 pounds of briquettes per hour. It's an automated electrical press that produces briquettes approximately two inches in diameter. It was designed to process wood waste but can handle other kinds of biomass, as well, according to Biomass Briquette Systems President Dave Schmucker. "The size and consistency of the material is very important in order to have the optimum performance and product output," he said. The press can handle biomass with a moisture content of up to 15 percent.

The small scale briquette machine has promoted the development of biomass briquette system in the USA. More and more people came to realize the importance of environment protection and clean burning. It also provides a chance to people to make charcoal by briquette press themselves.

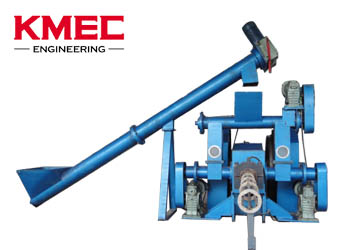

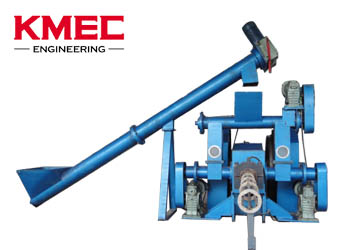

KMEC is the professional manufacture of

briquette machine and the complete production line of briquette. We have a series of briquette machine with different specification. Welcome to enquiry our products. We would like to provide you the most professional solution for briquette making.

---------------------------------------------------------------------------------------------------------------

Weed tree, miscellaneous tree and so on, do you have material like those? Do you have the intention of turning the waste into bonanza for you? Of course your idea can be put into practice and your lucrative business expectations can be realized now with Kingman briquette presses and charcoal machines.