Failture anlysis of briquette machine

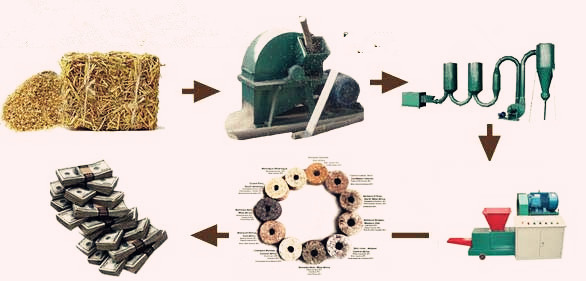

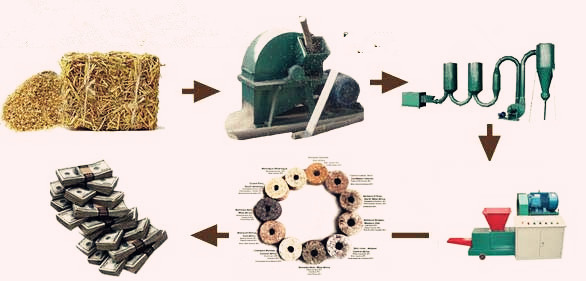

Biomass is an environment friendly, clean, cheap and versatile fuel. Biomass produced from organic compound such as agriculture residues (husk, cob, stalks, leaves, stems, shells, sticks). Also waste from bio-product industries like sawmills, plywood industries, furniture like sawmills, plywood industries.

During the processing of

briquette machine, sometimes malfunctions will appear. Next, we would like to introduce the technicians on how to deal with the fault.

Repeated restart

The repeated restart of the briquette machine is due to the low power supply of the equipment, which is not enough to cause the drive of the briquetting machine. First, use the multi meter to detect the power supply voltage of the machine, which must be measured in the load and open conditions, so as to determine whether there are power supply problems. The particular note is that power consumption of the open and closed states of the heater are far more different from each other. When supplying the electricity, the maximum power of the briquetting machine must be considered to ensure the normal power supply of the machine.

Abnormal sound

After a period of time, the briquette machine has abnormal sound during operation. As for this problem, you’d stop the machine and look up the reason. The first thing you should notice is the lubrication of briquette machine. If the machine works with long time, the lubricant parts should be added great to facilitate the briquetting process. Good lubrication ensures the smooth operation with stop. Sometime, it may be cause by the stones or other things which enter into the machine. The small things can not block the machine at first, but it may lead to the abnormal sound of the machine. If you can not stop the machine to examine the machine, it may destroy the machine, destroy the machine or injured the operators.

Spare part is wearing

Regular examine the spare part is important, especially for those which are quick wearing parts. When the finished briquette is not regular in shape, or the production is drop greatly, it maybe cause by the wearing of spare parts. To replace the easy wearing parts instantly is vital important for the normal operation of the briquette machine.

Then how to maintain the briquette machine

The maintenance of briquette machine is actually not too difficult. First you should know the components of briquette machine. It is composed of a speed reducer, motor and two rollers. The maintenance of speed reducer and motor has been mentioned in many books or other websites, therefore here we do not discuss in details. As the key part of briquette press, it means the rollers. Rollers are in set, which is composed by roller shell and roller core, among which roller shell is the most important since the roll sell determines whether the raw material can be normally pressed into briquettes. If the roller shell goes wrong, then the briquette press can hardly from regular briquettes.

However, how to maintain this important part roller shell? First of all, roller shell should be cleaned every time finish pressing to guarantee no impurities inside the machine. Otherwise, the material are hard to be cleared away after long tome no use, which could cause irregularly briquettes, or even unable to leave the mould. Once the briquette can not leave the mould or discharge irregular briquettes, it is necessary to adjust the roller shell, since long time operation is likely to cause shit to roller shell, as a result the formation cylinder can not form briquettes.

Above is one part of briquette machine maintenance. In the following days we will continue to introduce more knowledge about briquette machine.

------------------------------------------------------------------------------------------------------------

Green industry is becoming more and more popular in the world. The government provide policy subsidy to encourage the development of briquetting industry. Although the briquetting technology has many similarities usually comparing with the pellet fuel, it still has its own unique feature.