Biomass Briquette Machine

From biomass waste into biomass briquettes and charcoal

The available biomass material covers a wide range to be made into biomass briquettes and charcoal, such as sawdust, straw and stalk, rice husk, palm EFB and palm tree, bough and twigs and the like. Almost all plants can be processed with the biomass briquette machines and others shall be pretreated prior to briquetting. Speaking of processing equipment, the first striking us should be biomass briquette machines. The equipment is counted as the mainstay of a complete briquette production line. We hereby can take crop stalk as example to be made into briquette fuel. A complete straw briquette production project should cover several imperative sections, namely, cutting, crushing, drying, briquetting, cooling and packaging. Therefore, the equipment involved should be hay cutter, dryer, hammer mill, biomass briquette machine, conveyer, packing machine and so on. As we elaborated on the differences in screw-type briquette machine, mechanical tamping briquette machine and hydraulic briquette machine, you are supposed to pick up the most suitable model according to your expectation of unit-time yield, material species, investment budget and other factors. If you feel blurry about how to start a complete briquette production line, please feel free to contact us. We can deliver you a systematic design with comprehensive know-how.

Biomass briquettes, mostly made of green waste and other organic materials, are commonly used for electricity generation, heat and cooking fuel. These compressed compounds contain various organic materials. The composition of the briquettes varies by area due to the availability of raw materials. The materials are gathered and compressed into briquette in order to burn longer and make transportation of the goods easier. These briquettes are very different from charcoal because they do not have large concentrations of carbonaceous substances and added materials. Compared to fossil fuels, the briquettes produce low net total greenhouse has emissions because the materials used are already a part of the carbon cycle.

KMEC biomass briquette machines---the efficient helping hand with your business

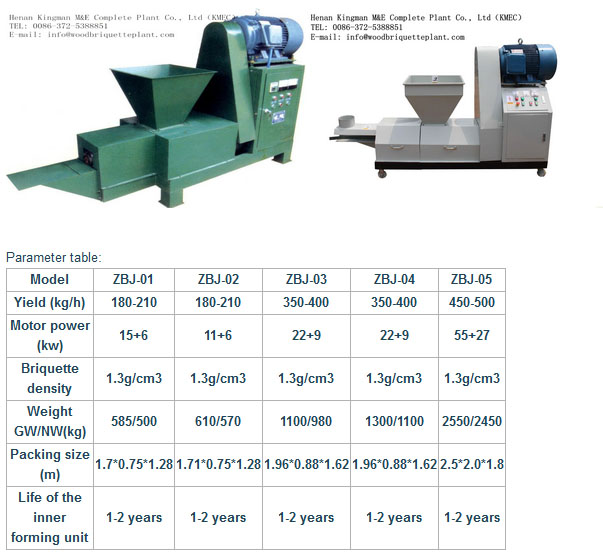

During the designing and manufacturing period, also based upon our experience, we do take into account the following factors in a synergized way to maximize the efficiency of the equipment, namely, the structure, power input, mold material, lubrication, dynamic coefficient, unit-time output, simplicity of operation, maintenance, dedusting system and costs. A long-term steady performance will influence not only the yield straightforward, but also plays a pivotal role in machine depreciation and biomass briquette quality. You investment will depend upon the aforesaid factors, which you should take into serious and premeditated consideration and budget. The clients can choose the type of machine on the basis of material, production requirement and function of briquettes.

----------------------------------------------------------------------------------------

Actually the structural design of straw briquetting machine comes from pellet mill. In china, there are three kinds of straw briquetting machine--mechanical press, Hydraulic press and screw press type.