Differences between charcoal furnace and charcoal kiln

What are the differences between charcoal furnace and charcoal kiln when using machine made charcoal equipment?

Earth Kiln usually needs comparative long time, about 7-8 days during carbonization process. The exhaust gas is bad for human health and pollutes the environment. The complicated operation make the production process of earth kiln is inconvenient. If temperature is not properly controlled, the charcoal is easy to be burn into ashes.

Comparatively the production cycle of charcoal furnace is shorter, about 1 or 2 days before discharging. And the carbonization chamber is closed which could decrease the aches. There is purification plant at the bottom of the charcoal furnace which saves manpower. What you have to do is stand by the side of the furnace to examine the temperature and pick up information.

------------------------------------------------------------------------------------------------------------

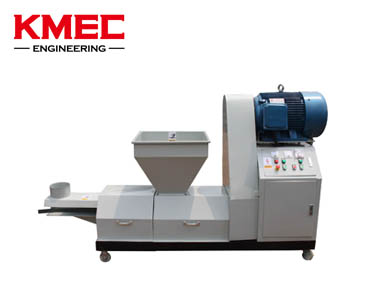

Biomass briquettes, or called manmade charcoal or regenerated charcoal or smokeless charcoal are squeezed from crushed sawdust by sawdust briquette press.

Our Charcoal briquette machine shows the features of high capacity, low energy consumption, compact and durable. Many performance data such as capacity, wood briquettes density, electricity consumption and wearable degree has reached advanced level.

Rice husk is a widely used agro waste for processing agro by-products, even though it seems useless. However, rice husk briquettes are quite useful as a kind of renewable green energy. You can realize biomass briquettes production with Kingman rice husk briquette machine and briquette plant.