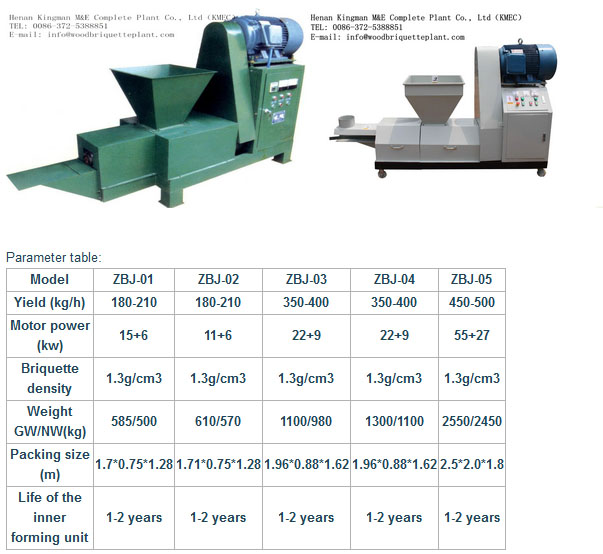

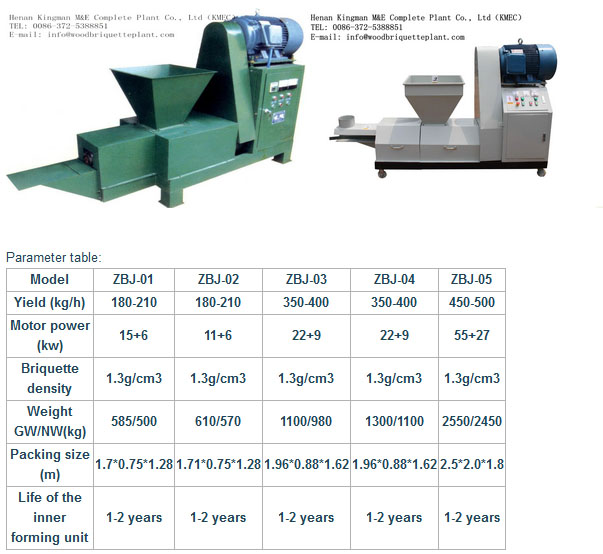

Installation and operation of straw briquette machine

Installation of straw briquette machine is as follows:

1.Main engine, power distribution cabinet and conveyor are put in place based on free space. Carefully check the motor, bolts and screws of transmission for solid or loose, when necessary, to adjust.

2.Connect main engine and power distribution cabinet with electric wire: connect terminal of motor of main engine and power distribution with six copper core power cables(≥16mm2). Contactor wiring order must correspond to the binding post order.

3.Connect the accessory of main engine to power distribution with electric wire: connect electric shock on the temperature controller wire to the terminal box under main engine frame; connect the cooling pump to the terminal box under main engine frame.

4.Connect feeding conveyer and power distribution with electric wire: connect terminal of motor of feeding conveyer and terminal of power distribution with the label feeding conveyer with three copper core power cables(diameter≥1.5mm2).

5.Connect the electric wire between finished product conveyer and power distribution, the same way as the above.

6.Carefully check the

briquette machine circuit of wire. Prevent electricity from cluster and leakage to ensure safety.

How to operate the briquette machine

As we know that the briquette machine plays an important role during the briquetting process. And if you expect your machine have a good performance, you have to pay more attention to the operation and maintenance of it. As the saying goes, detail decides success or failure. So, when you install your briquette machine correctly, you have to have the knowledge of how to operate the machine correctly.

1. Idle for a while. NO-load running for 2-3 minutes and if no blocking and anomalies, then you can feed material and start to normal production. If it is abnormal, you must to stop the machine immediately, check up the problems.

2. Pay attention to the feeding amount. You need to increase the feeding amount increasingly until the briquette machine produce normal products.

3. Before stopping the machine, it is necessary to make sure that the hopper is out of material.

---------------------------------------------------------------------------------------------------------------

Weed tree, miscellaneous tree and so on, do you have material like those? Do you have the intention of turning the waste into bonanza for you? Of course your idea can be put into practice and your lucrative business expectations can be realized now with Kingman briquette presses and charcoal machines.