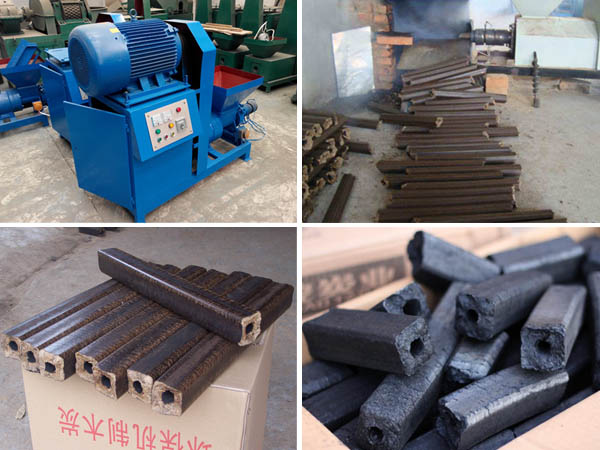

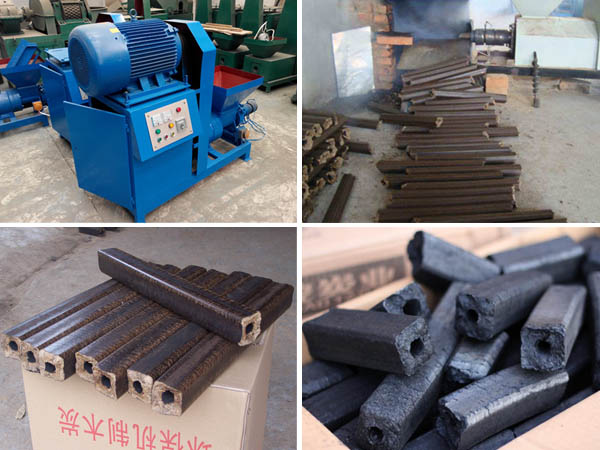

How to make high quality charcoal with sawdust briquette machine

The main production goal for those who invest in

sawdust briquette machine is high quality charcoal. In fact, it is not difficult to produce high-quality charcoal. It mainly need to master the skills of using sawdust briquette machine and technical indicators of raw materials. So what are the skills of using sawdust briquette machine?

First of all, you need to be aware of the use of raw materials. The moisture content of the raw materials used by sawdust briquette machine should be between 6% and 12%. Thus, you need to have a set of good drying equipment to make the humidity of raw material to achieve the best production effect.

Secondly, there should be a certain proportion of formula of raw material mixing. In the production process of sawdust briquette machine, the propeller used in the production line by using different raw materials is also different. Proper propeller should be used according to the production. The granularity and hardness of raw materials should be matched, so that the charcoal produced can be of high quality.

Finally, it is also very important to operate the sawdust briquette machine. The control of the temperature is the ultimate in sawdust briquette machine production line. The difference of temperature for making charcoal is closely related to the quality of the final products. Proper temperature control can reduce the problem of cracking briquettes and other problems, thus improving the yield of

briquette machine for sale.

Under normal circumstances, the working time of sawdust briquette machine is shift work. Generally, the working time of sawdust briquette machine is 8 hours a day. After eight hours working, the operator of sawdust briquette machine need to stop the machine for maintenance.

But in fact, the bearing capacity of sawdust briquette machine is 12 hours, that is apart from the eight hours working, the briquette machine for sale can also be used for normal production for 4 hours, and that a total of 12 hours is the full production of sawdust briquette machine. Then, the machine should stop and maintain timely. Otherwise, the sawdust briquette machine would be damaged if beyond the bearing capacity of the equipment and normal maintenance can not be made.