Briquette Press Development Opportunities---I

Development Opportunities of Briquette Press---I

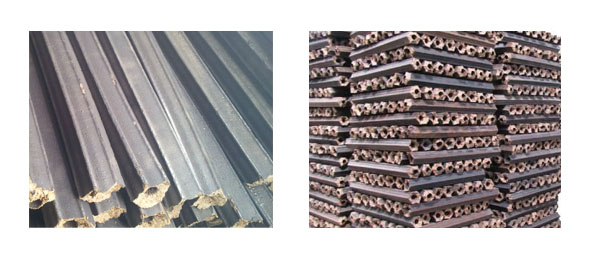

The briquette industry is a quite booming one; nevertheless appropriate interventions can enable it to expand to a scale that can significantly impact the fuel market. Opportunities exist for all scales of business to grow and tap into the available markets and with targeted support the current briquette industry can be developed from a sporadic spread of small enterprises into a widespread and self-supporting industry, which indicates a wave of development opportunities for

briquette press is coming up. Areas of intervention include improving the available technology, fostering the skills of entrepreneurs, facilitating capital and developing the delivery network. There is an opportunity to grow the hundreds of briquette microentrepreneurs from producing 2 tonnes per year to 20 tonnes and then 200 tonnes, but it needs cooperation between raw material provider, briquette manufacturers and briquette press suppliers. Most barriers to growth appear at a production level of around 200 tonnes per year, and while some will be able to overcome these challenges and grow, it is more likely that production in the region of 2,000 tonnes per year will be achieved by new entrants who have the necessary resources and commercial experience to open a dedicated factory. Here it is necessary to attract investment and seed funding to get a business of this scale off the ground. It is recognized that many people who engage in micro-scale operations in rural and peri-urban areas cannot be developed into highly entrepreneurial business people if it is not what they want to do.

Link to Briquette Machine

Link to Briquette Machine

The high potential entrepreneurs are linked with loan providers and briquette press or briquette plant suppliers as it is they who would benefit most from powered machinery and extra capital. Medium potential enterprises are those that show willingness to produce quality briquettes but are unlikely to grow and are best helped by supporting them to produce and sell high standard products. Low potential enterprises can’t or won’t produce quality briquettes for a variety of reasons and more impact can be gained by directing resources at others.

High prices relative to wood and charcoal; difficulties with equipment maintenance; unclear policy and regulatory supply, relative lower calorific values; and high upfront capital costs have been noted as the primary challenges to scaling up of the enterprise. Interest in briquetting and associated technologies has experiences resurgence in recent years due to technological developments that are changing the economics of the final products, an acute decrease in wood fuel resources, an increasing in the cost of other alternatives including kerosene for cooking, as well as a rise in environmental awareness of the impacts of unsustainable biomass energy. This has yielded mixed results across projects, regions and countries.

Securing Supply

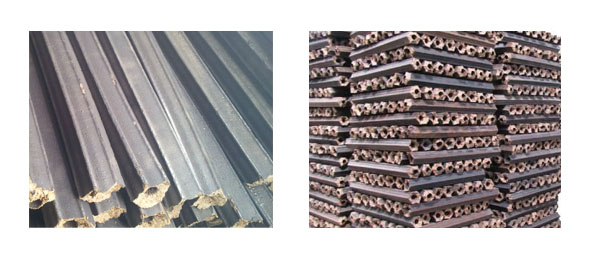

For larger producers of both carbonised and non-carbonised briquettes a reliable and consistent source of feedstock is vital and a professional briquette press supplier also means a lot. Large agricultural producers, forestry projects and industries need to be willing to offer and enter into business arrangements with briquette manufacturers. While competition for raw materials is certain to increase, contracts with waste producers can secure a reliable supply. And a good briquette press supplier can offer the best briquetting technique to process excellent quality briquettes. There are several considerations which shall be take into account:

Availability: Existence and accessibility of biomass in bulk; seasonal variation; degree of centralization; competing uses; clarity of ownership;

Conversion Potential: Physical suitability for the briquetting technologies available, their cost, efficiency and environmental performance;

Fuel Quality: Energy value and performance for desired use;

Enterprise Potential: Willingness and capacity of the waste owner, briquette producer and briquette press supplier to collaborate in a briquetting venture.

Many medium-scale producers (200 – 2,000 tonnes per year) who serve domestic markets use locally sourced charcoal dust as a feedstock in an attempt to avoid the inefficiencies of transporting and carbonising raw biomass from agricultural wastes. It could therefore be beneficial to process (carbonising, milling and sieving) biomass at its source rather than in a centralized location. Maintaining control of feedstock quality remains a challenge of this distributed model, however at this scale the lack of low-capital carbonisation techniques and poor economies of transportation means that building a supply network of small-holders and subsistence farmers is proving to be a more successful model than operating centralized system to process agricultural wastes.

The increasing growth of energy needs and price drives the expansion of briquette production scale with large industrial briquette making plants and the briquettes application which means the biomass briquettes are now having a promising market. Briquette press can be used by the industrial boilers for steam and heat generation, food processing industries for drying, etc, textile process houses for dying, bleaching, etc, clay products industries, such as tile making, pot firing, etc, and domestic using for cooking and water heating. If you are looking for high-quality briquette press, please feel free to contact us.

------------------------------------------------------------------------------------------------------------

One of the major challenges that micro entrepreneurs face in expanding their business is accessing the appropriate finance. Most micro entrepreneurs lack the capital to engage in marketing activities, research and development or to purchase equipment that would help their business to expand. There are many challenges to bringing finance to micro- and small-scale entrepreneurs at the base of the pyramid.