Differences and similarities between briquette and pellet

What are the differences and similarities between briquette and pellet?

Biomass material such as rice husk, wheat straw, maize stalks and peanut shell as well as sawdust, saw shavings and wood chips can be produced either into briquette or pellet under high pressure until the lignin softens and binds the material together by the

briquette machine or pellet mill. The use of compression technology increases the bulk density of raw materials and results in lower transportation costs, reduces storage volume and easier handling. Meanwhile, it improves energy density and more homogeneous composition provide better options for burning, and lead to a more efficient combustion process. But what are the differences between briquette and pellet? In the following content, we would introduce the differences of briquette and pellet in detail to make users make better use of the two biomass fuels.

The similarities of briquette and pellet:

1. Both briquette and pellet are compacted and tightly squeezed form of biomass with super high density of about 700kg-1100kg/cm3 due to starkly different material attributes;

2. Both briquette and pellet can be used as renewable biomass fuel to replace fossil fuel like coal or natural gas or petroleum;

3. Both of them can be applied for domestic range and industrial scale for heating or power production;

4. Both briquette and pellet can be stored and transported with less floor space for the convenience of long-term retention and transportation.

5. Both of the two will be produced by adopting familiar processing procedures.

At length, the technological process for both briquette and pellet includes (debarking--chipping--screening--pulverizing)--drying--conveying--briquetting(pelletizing)--conveying--packing.

The differences between briquette and pellet:

1. Briquette covers a wider range of raw material to be processed, such as agricultural and forest residues, metal scraps, domestic garbage and so forth but nowadays in the biomass pellet field, raw material sphere is mainly constrained to biomass. Even some newly developed models processing metal scraps or domestic residues are of unstable performance. Besides, briquette machine can uniquely manufacture hardwood material into briquettes, overshadowing pellet mill which is good for softwood material.

2.

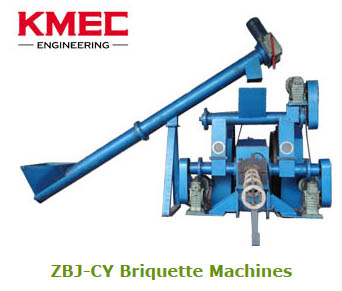

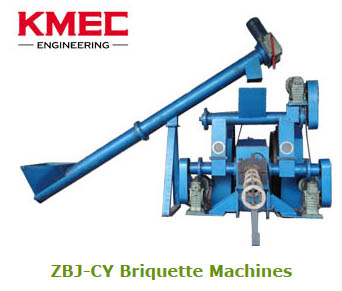

Briquette machine can process either softwood or hardwood favorably. Hardwood can be processed into pellets. But in the wake of improvement in biomass pellet inspection and regional regulation, not least across Europe, DIN requirements for pellets have been formulated and released officially. Disqualified pellets will not meet the demands for European pellet market. Especially Kingman

mechanical stamping briquette machine and

hydraulic briquette machine can achieve an even better yield and performance.

3. Biomass briquette can be carbonized into charcoal as a new form of coal and also used for BBQ while pellet will be consumed directly. The deepening processing of briquette remains a markedly unique trait.

4. The main disadvantage of densification is the relatively high cost of input energy, which is needed for the production of pellets and briquettes. This will also increase the price of the output product. The output product is in the form of briquettes or pellets. Calorific value, water content and chemical composition are approximately same for both, but the density and strength is usually high for pellets. The main difference is in size. Pellets are 4-5 times longer that their diameter (ranging between about6-12mm), while briquettes have a diameter of 80-90mm.

5.Briquettes are primarily used instead of firewood for manually charged domestic stoves. Pellets can be used in automatically charged stoves and boiler due to their good flowability, uniform water content, grain size and chemical composition.

KMEC provides all kinds of briquette machine with stable performance, excellent quality and reasonable structure. If you need biomass briquetting press, please feel free to contact us.

------------------------------------------------------------------------------------------------------------

Kingman biomass briquetting machine and biomass briquetting plant will be your reliable and solid foundation for a success in your business.