Use Briquette Machine-Case Study3

Briquette machine has the features of high performance and eco-convenient way of producing fuel briquettes. It offers the way to get biomass briquettes with no smoke and ash. This is the reason why briquette machines are becoming more popular in to the industries. The trimming down of forest and natural energy fuels like wood and natural gases would be the most eye catching issues in present era. The following is an example of Margret who is running briquette business.

Margret runs a briquette making business. She decided to start her briquette business with manual

briquette machine. She began by making briquettes from charcoal dust, grass and cassava flour but has since expanded her operations through the purchase of briquette machines and carbonisation kilns. She employed several permanent and some casual workers. She estimates that her average sales would be around 120tons per month and she sold to local households, institutions, schools and poultry farmers and attracted customers from as far as 20km away. To promote her business, Margret gave out free samples to potential customers and would go house to house to talk to people about her briquettes. She also talked at local gatherings and community meetings to promote her business and displayed her briquettes outside her shop by the road side where her workers would explain their benefits to interested people. GVEP taught Margret to keep records for her business. At first she was making a loss on her briquettes, but now she knew how to balance her books she had recalculated her pricing and could make a decent earning.

She expressed that "I would just mix all the ingredients together. The mentors showed me how to use the right measures. In 10kg of charcoal dust I use 1kg cassava flour and now my briquettes production is free from smoke and my sales have increased”. Margret has since registered her business and opened up a briquette bank account. She also successfully applied for a loan from her country. As a result, she got a loan, which she used to improve on the quality and quantity of briquettes production. Part of the money was used to procure briquette machine. As a result, she has been able to transform from manual to mechanized production and has opened up two branches in neighbouring districts. She has also hired the services of more permanent workers handling sales and marketing, and she has been able to increase her customer base by 70 more clients.”

To get production to multiple thousands of tones per year, imported machinery is required. Under the help and guidance of GVEP, she got a loan worth Ush 2.5million, which could be used to improve on the quality and quantity of briquettes production. Part of the money was used to procure a briquette-making machine. As a result, she can transform from manual to mechanized production.

In 2010, the Uganda Investment Authority (UIA) put forward investment proposals for a 70-tonne per day (20,000 tonnes per year) manufacturing plant for briquettes made from municipal solid waste collected from households and surrounding markets in Kampala. The supply and distribution models of businesses operating at each level of production differ, as do the challenges faced by each.

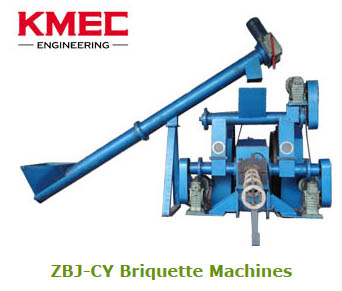

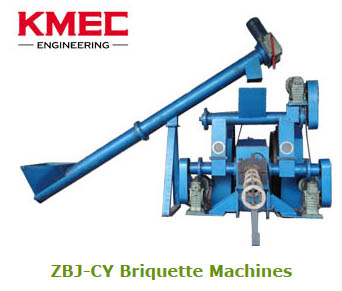

The manufacturers of briquette machine help in converting industrial waste for generating electricity that aid the farmers to raise their incomes. Briquettes plant transforms ordinary industrial and forestry waste into dense briquettes, with a volume reduction to save storage space, reduce loss during transportation and storage, makes biomass waste more easy and effective! As a briquette machine manufacturer with years of experience, KMEC provides all kinds of briquetting equipment and briquette machine product line. We are looking forward to receive your enquiry.

------------------------------------------------------------------------------------------------------------

Use Briquette Press-Case Study I

With access to the energy services mentioned in the previous sections, people are able to improve their livelihoods in a variety of ways. These changes can help shift from a subsistence existence into more productive communities where people are able to enhance their livelihoods through their own efforts.