What is Briquette(2)

2. From Technology to Business

The first section gave an overview of briquetting as a technology; now read about the business angle to briquettes.

Why briquetting could work for you:

-

It can use either no machinery at all, or low cost machinery (as little as US$70), so you can start small;

-

Raw materials are often readily available? Can either be grown or obtained from factories as waste;

-

It requires low technical skills for you as an entrepreneur.

Market

Your business needs users close by. The two key markets for briquettes are likely to be 1) households or 2) institutions:

The household market comprises individual consumers who need fuel for cooking and heating. Briquettes can be a great substitute for charcoal. Key benefits include reducing household fuel bills and longer-lasting burning.

The institutional market (e.g. schools, hospitals, hotels) could be made up of organisations that utilize charcoal and firewood for their production or cooking processes. The use of briquettes could prove to be a more economical, healthy and environmentally friendly way to provide energy.

Gaps in the briquette sector

1.Small and micro production across the region

2.The subsector lacks guidelines

3. Lack of technical skills in making good briquettes

4. Most are manually produced or with simple machines( mechanical or electrical)

5. Lack of good quality machine in the market

6. Awareness about the value of briquettes is low

Issues to consider

-

NO "one size fits all" product to reach the poor

-

Reaching poorest countries to be a challenge. Fuel switching is difficult and briquettes must outweight charcoal in costs and long lasting fuel

-

Success in scaling up energy businesses in still low. Last mile delivery chain dependent on:

1>high skills and knowledge transfer

2>appropriate marketing

3>high end value products concentrated in urban markets

4>initial subsidies

5>adequacy of government policies( e.g. In Uganda, no tress to be cut and therefore more interest in briquettes)

Business Model 1: Micro Briquette Producer

A popular business model is to be a producer of briquettes; that is, collecting and processing raw materials and selling direct to consumers or wholesalers. Some investment would be needed to get such a business off the ground, but the amount could be a quite small, less than US$200. Comparing this to monthly sales revenues (up to US$300 monthly) it is clear such a briquetting business could be profitable.

Business Model 2: Briquette Trader

Another model (if producers already exist in the area) is briquettes trading; buying in bulk from a producer and selling at a convenient location to customers at a markup. This could be a good diversification opportunity for already existing charcoal dealers.

3. Technical Pointers

How would I actually go about making briquettes? Below is a set of step-by-step pointers:

Step-by-step production

i.Sorting/sieving: all unwanted materials or large biomass waste are removed to ensure that all the feedstock is of the required size. For example, the raw sawdust you collect could contain unwanted larger pieces of wood. These can be sieved out with a wire mesh.

ii.Shred biomass materials into small pieces: The biomass materials are chopped into small pieces so as to enhance their workability and compactness. The process is dependent on the type of biomass feedstock. For example, coffee husks and saw dust would not require shredding but materials such as groundnut waste, bagasse, wheat straws, barley and maize straws and cobs would need to be chopped into small sizes. In the case of carbonised biomass, the materials would need to be grounded into small pieces after they have been carbonised.

iii.Mixing: This process is done in situations where you want to use a range of different feedstock to optimise the burning characteristics of the final fuel. For example, biomass materials with high ash content could be mixed with biomass material of low ash content. Biomass with low energy content such as papers can be appropriately mixed with those of high energy content. This helps to attain the right quality (long burning period, non-smoking and odour free) that will make briquettes competitive in the market.

iv.Binder: In addition to biomass mixing, an appropriate binder is added and mixed with the biomass thoroughly. This enhances the compactness of the biomass materials and prevents them from falling apart. An example of such binders include starch or clay rich in biomass.

v.Adding water: Water is usually added to the feedstock to make them loose and easy to work on. Some biomass materials require to be soaked in water for a number of days to ensure that they are soft enough to work on.

vi.Compaction & Drying: Finally the feedstock is ready for compaction, either by machine or by hand. The briquettes will need to be left to dry for up to a week.

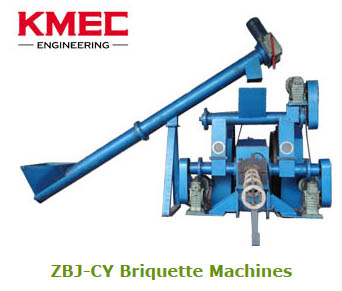

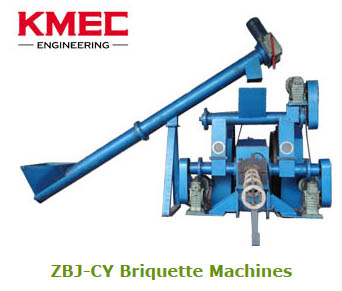

Briquette Machine for Sale! KMEC is capable of offering a package of project with delicate designs and high-quality briquette equipment to move forward with clients from all over the world! We are specialized in the design and production of all kinds of briquette machine. The products of our company are with stable performance, excellent quality, innovative design and reasonable structure. Cooperation in good faith and outstanding service are our main advantages, which make our company develop rapidly throughout the country and praised by a vast number of customers. We sincerely welcome customers to consult, negotiate and order!

------------------------------------------------------------------------------------------------------------

Charcoal are mainly produced from screw briquette machine. Kingman stamping briquetting machine is capable of extruding biomass pellet and pressed briquette, and biomass briquette plant will help you cater to demands for different types of customers, either for biomass briquettes or for biomass pellets or charcoal.