- info@woodbriquetteplant.com

+0086 372 5388851

+0086 372 5388851

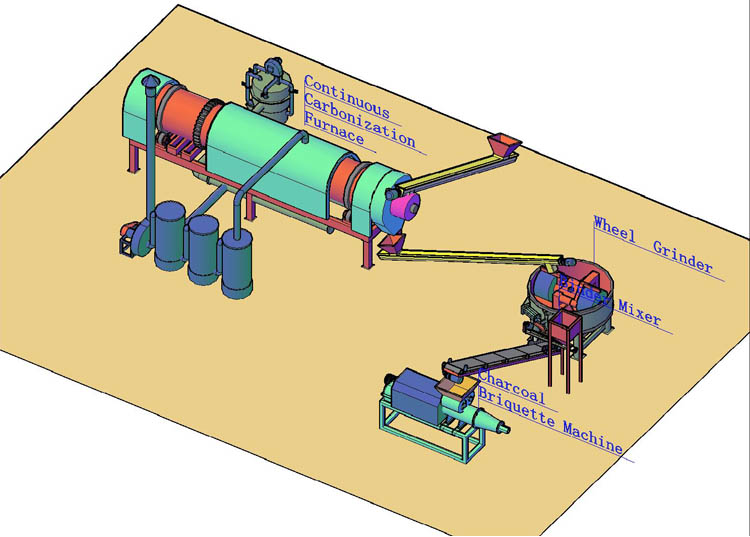

Carbonization furnace, also called continuous carbonization furnace, is an ideal equipment for high-temperature distillation and anaerobic carbonizing of carbon-containing biomass materials (diameter< 15mm) such as sawdust, peanut shell, rice husk, coconut shell, palm shell, wood block, straw and bark under certain conditions. If the equipment is specialized in carbonizing rice husk, we can also call it rice husk carbonization furnace.The carbonization furnace is a horizontal structure, and the carbonizing process is a rotary motion carbonizing.

Traditional charcoal carbonization furnace can not realize continuous carbonizing, resulting in low economic benefits; the carbonizing process will release a lot of smoke and dust, causing air pollution, which is not in line with environmental protection policies. Continuous carbonization furnace adopts the advanced technology of circular combustion, and the combustible gases such as carbon monoxide, methane and oxygen produced during carbonizing process are recovered and purified. It not only solves the problem of environmental pollution caused by heavy smoke generated in carbonizing project in traditional charcoal carbonization furnace, but also achieves self-sufficiency, solves the problem of heat energy required by equipment, and makes up for the deficiency of traditional carbonization furnace, which meets the requirements of environmental protection and the concept of sustainable development.

Specifications of carbonization furnace:

| 1m× 12m single drum | 15KW 400-500kg/h |

| 1m× 12m double drum | 18.5KW 500-600kg/h |

| 1.2m× 12m single drum | 22KW 600-700kg/h |

| 1.2m× 12m double drum | 22KW+3KW 700-800kg/h |

| 1.5m× 12m single drum | 30KW+3KW 1000-1200kg/h |

| 1.5m× 12m double drum | 30KW+3KW+3kw 1000-1200kg/h |

| Main technical parameters | Details | |

| 1 | Type | Dry Distillation |

| 2 | Voltage | 380 V |

| 3 | Power | 3 KW |

| 4 | Capacity | 500-600kg/h |

| 5 | Weight of the Main Machine | 3.5 Tons |

| 6 | Weight of the Whole Production Line | 8.5 Tons |

| 7 | Diameter of raw material | <=30mm |

| 8 | Working continuously | 24 Hours |

| 9 | Dimension of the Main Machine | 1.0 * 9.0m |

| 10 | Inner Furnace Temperature | 350-500 °C |

| 11 | Carbonized Pipeline Temperature | 500-700 °C |

| 12 | Effective Volume | 7 cubic meters |

When the carbonization furnace works, the materials are firstly burned in the gasification furnace. After being sprayed, cooled and purified, the flue gas generated in the pipeline becomes combustible gas (carbon monoxide, methane, ethane, etc.), which is used as the heat of initial carbonization to heat and carbonize the raw materials in the carbonization furnace (such as machine-made core rods, waste logs, bark, coconut shells, household garbage, etc) . When the temperature reaches 300 degrees Celsius, the carbonization furnace begins to carbonize raw materials and produce smoke; After spraying, the flue gas becomes combustible gas, which is cooled and purified by the cooling and purification system, and continues to carbonize, and then the gasifier stops working.

1.Equipped with a control cabinet and intelligent control system, the operation is intelligent and simple.

2.Configure a frequency conversion feeder to feed automatically. The feed speed can be adjusted.

3.Equipped with a rotary drum carbonization host to meet the production requirements.

4.Energy saving and environmental protection, make full use of the gas generated by raw materials, and purify the circulating spontaneous combustion for machine heating.

5.Configure a cooling discharging machine to cool the final product and export the final product.

6.It can work continuously, while conveying raw materials and discharging carbon.

7.High production efficiency and high output.

Why choose us?

KMEC provides complete feeding system, carbonization, control and test system, waste gas treatment equipment and other related components. We have accumulated rich experience in the production of different types, sizes and carbon raw materials. For some areas rich in biological resources, especially those with high output of wood and fruits including coconuts, the production of activated carbon can make full use of local natural resources and gain a competitive advantage in raw material prices.

Our equipment has patented design and has obvious advantages in producing high-quality carbon; High production efficiency, our daily production capacity is as high as 6 tons; Equipped with a complete production line to meet the needs of biomass carbon manufacturers; Advanced equipment can recover the heat generated in the production process, improve the utilization rate of raw materials, and greatly reduce energy consumption and production costs.

KMEC has a professional team and perfect service. We can help you build your carbon production plant from scratch. If you need it, we can also help you expand and improve your existing plant. Rich experience, let us know your needs better. Complete pre-sale, in-sale and after-sale services allow you to choose us with confidence!