Three important factors upon briquettes quality

Important factors upon biomass briquette quality

Quality of briquettes in the first place shall be guaranteed to lay a foundation for charcoal production. Both theories and practices have solidly proved that the moisture content of material, briquette machine propeller and proper temperature are the three irreplaceable factors for manufacturing supreme-quality charcoal.

Some Raw Materials

1. Material moisture content for briquette machine

1. Material moisture content for briquette machine

Moisture content is mainly affected by the feed stock specise and its properties. The optimal moisture content is around 10-18%. When the moisture content is lower than 10% or higher than 18%, particles of feed stock are not consistent and the briquettes are tend to fall into pieces.

Before putting the feedstock into briquette machine, moisture content of feedstock shall be remained about 5%-12%. Otherwise, moisture content of less than 5% will lead adversely to loosened briquettes; that of more than 12% will result in twisted or bent briquettes with lower density.

Generally, material possessing more than 50% moisture content (such as freshly lumbered material or twigs) is bound to drying one or two times prior to briquetting. If material before putting into briquette machine has been naturally dried in the open air or exposed under sunlight for one or two days, then one-off drying will be quite enough. Briquetting demands strict moisture content.

Some clients may ponder over how to distinguish the moisture content of raw materials? Technically, hydrometer is a better way and Kingman can offer the device or clients can prepare by themselves. But operators with accumulation of experience can tell the difference by their palms and fingers. Grasp a handful of dried material and hold it tightly, then let go of the material to see whether all the handful material will scatter loosely. And material ought to be observed with much lighter color than the moist. Besides, some pricked feeling may happen to your fingers and palm. As per the above descriptions, it has been dried well. The following check goes to propeller of briquette machine when the moisture content of material is adjusted well.

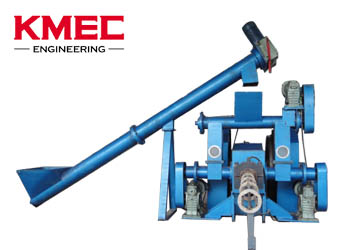

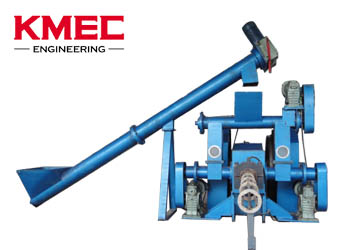

This is counted as another decisive factor. Since it is a quick-wear part of briquette machine, in particular, the front end as the spirally squeezing head at high speed will confront material with super high pressure under the condition of high temperature, also with abrasion occurring to the screw head. Therefore, the front end is easily dwindled or dented by harsh material. If so, the screw rod or called propeller shall be renovated. Otherwise, qualified briquettes cannot be pushed out or even no briquette can be produced. Briquette strength is increased with the increasing compacting pressure within the compacting limite of the feedstock. When the pressure is increased, the atmospheric humidity in the feed stock is decreased and briquette durability is increased.

Propeller is the main and important part of briquette machine. The bearing puts great pressure on the propeller to squelch the sawdust into molding barrel. Although the propeller is quick wearing, it can be repaired and reuse. It need to be repaired every eight hours with wear-resistant electrode. The propeller should be welded and grinded after using about five to seven days. And, nearly a month, it needs to be replaced with a new one.

Repair method of propeller: Preheating the parts of propeller system which need surfacing. When the temperature reaches 200 degrees, weld it by the wear-resisting electrode. Welding thickness should be 1-2mm larger than the desired thickness. Cool it after welding. When the temperature is below 50 degrees, remove and grind it on silicon wheel. No collision and percussion on the repaired propeller and it should be stored carefully for using.

Link to how to renovate propeller

3. Working temperature of briquette machine

Link to how to renovate propeller

3. Working temperature of briquette machine

Pressing temperature influences brqiuette quality and strength significantly. Pressing temperature impacts the soften and excretion of lignin which will function as natural bonders to join the firebers of the feedstock to form solid high density briquettes.The sleeve temperature, also referred to squeezing temperature, shall stay around 260-300 degrees centigrade. The adjustment of temperature lies in the character of feedstock. In the first place, it is entitled to be known that pre-heating of sleeve with the heating coil is to speed up softening of lignin of material and increase cohesiveness. However, overheating may excessively soften material squeezed in a favorably smooth speed but extruded briquettes are nothing but just soft. To the opposite extreme, cohesiveness of material will drop down, and briquettes also due to loosened structure will be cracked with crevice. But the temperature for briquetting alters from one sort of material to another. At times, clients prefer mingling more than one kind, or from time to time, softwood briquetting is quite different from that of hardwood. We can simply share with you some examples herewith but for details, please contact us and our technicians will reply at length. It is acknowledged that bamboo material is compatible with a lower temperature value about 260-300 degrees centigrade while 300-320 degrees for rice husk and wheat stalks. The factor shall be comprehensively integrated with moisture content of material. And surface hue of briquettes to this end is influenced as well.

In a nutshell, the three factors are closely connected with the performance of briquette machine and negligence upon any of them will lead to an adverse outcome. When you handle a briquette machine, especially, the screw type briquette machine, you should attach comprehensively more importance to them. KMEC provides all kinds of

briquette machine with elegant appearance, high efficiency, stable performance and low investment. We are always ready and glad to receive your enquiry about our products and hope to be your sincere cooperator and friend.

-----------------------------------------------------------------------------------------------------------------------------

Following with the development of economic, more and more people come to realize the importance of air pollution and carbon emission. People’s healthy and living condition greatly concerned with the air condition. In china, we comes through the unexpected bad whether condition ever before, everyone in china has the experience of frog and hazy.