From Briquette Machine to Charcoal Furnance

Pricing of charred briquettes

At present, the prices of charred briquettes are varied as per market demands. Here across China is a benchmark of pricing but specifically, industrial needs for charcoal due to the low requests for appearance and length will lower the prices. BBQ charcoal is various in price from one city to another in terms of the development level of the city. Regarding the overseas markets, European and North American and Oceanic markets account for a larger part while South American and Asia as emerging markets are also worldwide suppliers. African region cannot be neglected thanks to the huge potential for enlarging markets and capitalizing upon abundant material resources.

Deep understanding of carbonization

Deep understanding of carbonization

Wood consists of three main components: cellulose, lignin and water. The cellulose, lignin and some other materials are tightly bound together and make up the material we call wood. The water is adsorbed or held as molecules of water on the cellulose/lignin structure. Air dry or "seasoned" wood still contains 12-18% of adsorbed water. Growing, freshly cut or "unseasoned" wood contains, in addition, liquid water to give a total water content of about 40% to 100% expressed as a percentage of the oven dry weight of the wood. The water in the wood has all to be driven off as vapour before carbonization can take place. To evaporate water requires a lot of energy so that using the sun to pre-dry the wood as much as possible before carbonization greatly improves efficiency. The water remaining in the wood to be carbonized, must be evaporated in the kiln or pit and this energy must be provided by burning some of the wood itself which otherwise would be converted into useful charcoal.The first step in carbonization in the kiln is drying out of the wood at 100°C or below to zero moisture content. The temperature of the oven dry wood is then raised to about 280°C. The energy for these steps comes from partial combustion of some of the wood charged to the kiln or pit and it is an energy absorbing or endothermic reaction. When the wood is dry and heated to around 280°C, it begins to spontaneously break down to produce charcoal plus water vapour, methanol, acetic acid and more complex chemicals, chiefly in the form of tars and non-condensible gas consisting mainly of hydrogen, carbon monoxide and carbon dioxide. Air is admitted to the carbonising kiln or pit to allow some wood to be burned and the nitrogen from this air will also be present in the gas. The oxygen of the air is used up in burning part of the wood charged.

The spontaneous breakdown or carbonization of the wood above a temperature of 280°C liberates energy and hence this reaction is said to be exothermic. This process of spontaneous breakdown or carbonization continues until only the carbonised residue called charcoal remains. Unless further external heat is provided, the process stops and the temperature reaches a maximum of about 400°C. This charcoal, however, will still contain appreciable amounts of tarry residue, together with the ash of the original wood. The ash content of the charcoal is about 3-5%; the tarry residue may amount to about 30% by weight and the balance is fixed carbon about 65-70%. Further heating increases the fixed carbon content by driving off and decomposing more of the tars. A temperature of 500°C gives a typical fixed carbon content of about 85% and a volatile content of about 10%. The yield of charcoal at this temperature is about 33% of the weight of the oven dry wood carbonised - not counting the wood which was burned to carbonise the remainder. Thus the theoretical yield of charcoal varies with temperature of carbonization due to the change in its content of volatile tarry material. (24, 26, 31). Table 4 shows the effect of final carbonisation temperature on the yield and composition of the charcoal.

The unbalanced exploitation of charred briquettes market

The unbalanced exploitation of charred briquettes market

Charcoal based upon use of briquette machine has been developed for a stretch of decade years but the booming in fact started since the recent 5 years due to state bans in a lot of countries on random lumbering and open-air burning of crop stalks, due to which earthen kiln carbonization has been curbed. However, some areas still obstinately stick to burning underdeveloped charcoal which is of low combusting performance and of severe pollution. In addition, application of briquette machine and projects of briquette plants are also influenced by material supply, market of charcoal and briquettes, power sector, site and financial preparations, not least raw material supply and end-user market. That is the reason why both the material-led market and product-oriented market crave for briquette machine and carbonizing furnace. The striking point is how to make full use of material and perfect the transportation and logistics of briquettes and charcoal from raw material markets to end-user markets, from which an industrial chain comes into being and booming.

Nowadays, the demand for charcoal is growing and charcoal is widely used in more and more fields. Charcoal briquettes can be widely used in industrial, agricultural, animal husbandry and catering fields, as well as residential heating, BBQ and so on. They are also excellent for their cheap price, high quality, light weight and compact size. The machine-made charcoal made by the briquette machine has replaced the charcoal made by traditional earth kiln, which greatly reduces the production cost and improves the economic profits.

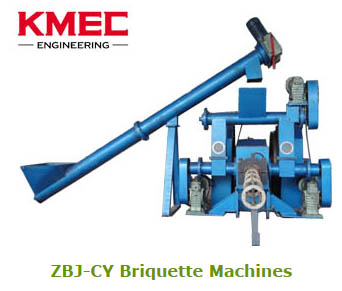

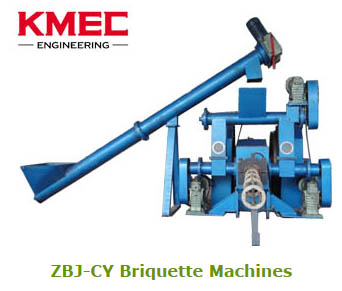

Since its establishment, KMEC has been committed to the researching and manufacturing of

biomass briquette machine and other biomass fuel formation equipment. We can not only provide clients with a series of complete set of machinery including the biomass cutting, crushing, formation, cooling, package, etc. KMEC also supply the intimate and thoughtful solution for the clients so as to meet various requirements.

-----------------------------------------------------------------------------------

We would like to make a detailed comparison between screw type briquette machine, mechanical stamping briquette machine and hydraulic briquette machine so that you will comprehend the three types of briquette machine well.