Charcoal Briquette Making Machine and Fuel Briquette Machine

The must-know notice of investment in charcoal briquette making machine and briquetting plant

As you have the intention of setting up a briquetting plant or investing in fuel briquette machine, there are several factors, or called pre-conditions you should take into account.

1. The briquetting plant you want to construct shall stay far apart from downtown city or other places close to dwelling spots and resident community.

2. There must be sufficient power supply for the briquetting plant. In this respect, please inform us of your available power supply so that we can deliver the uniquely designed briquette plant project. Otherwise, the inadequate supply may not drive briquette plant to run.

3. Water resource and fire distinguishers should also be needed just in case of fire hazard due to the use of inflammable raw materials.

4. It is imperative that space for installation of briquetting plant is enough to hold charcoal briquette machine, crusher, charcoal stove and other charcoal machines. Besides, there should be sufficient room to put raw material away and store finished products. As for space use, it lies in the yield you demand every day or per hour. Therefore, you should also make sure the production output you are going to put into practice.

5. In the very beginning, due to the lack of operating experience, you are supposed to arrange two persons taking care of one charcoal briquette making machine. After a while, with experience accumulated, a single person is capable of handling one fuel briquette machine.

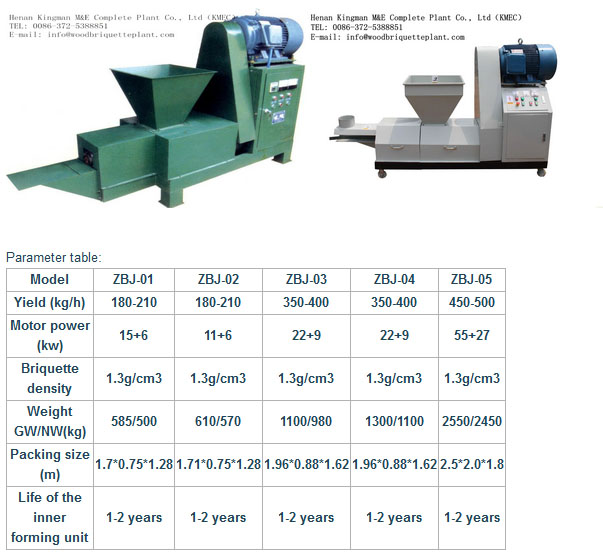

Get to know the fuel briquette machine now

All in all, the above-mentioned should be considered and we would like to share potential clients, for we expect that your investment can be lowered and efficiency enhanced with our shared experience.

The procedures of charcoal briquette making and handling briquetting plant

The procedures of charcoal briquette making and handling briquetting plant

Roughly, there will be 4 steps to start briquetting plant:

1. Crushing. Required material size for charcoal briquette making is about 4 or 5mm. If wood logs, tree branches and twigs or saw shavings are to be used, they shall be pulverized ahead of briquette making. Given the sawdust put into use, you should also distinguish the purity of material, otherwise, a sifter is suggested being used to remove metal scraps or other foreign matters.

2. Drying. The demanded moisture content of material remains around 13%-15%. Fresh chopped or crushed material may be subpar for making charcoal briquette. Before put into charcoal briquette making machine, a drying system is needed as well.

3. Fuel briquette machine will be the most important one to make briquettes.

4. Last but not least, briquette charcoal machine, namely, charcoal stove or carbonized furnace, will be put into use to carbonize briquettes into charcoal.

Link to briquette charcoal machine

Working Principles of charcoal briquette machine and fuel briquette machine

Charcoal was initially produced directly from cut wood logs and split twigs. Material would be carbonized after a while for insufficient combustion lacking of oxygen and on this occasion moisture and wood tar would be removed in a dry distillation way. However, the original production of charcoal posed a threat to human respiratory system exposed directly to suffocating smoke produced during the process. Besides, the quality of charcoal is of bad use. Based upon the working principles, we developed and upgraded both chacoal machine and fuel briquette machine. Briquettes will be processed in the first place and then put into charcoal stove for carbonization. Thanks to the process, not only the quality of charcoal is improved, but also the thermal value of both charcoal and briquettes are increased and fewer emissions can be realized.