How to make briquettes by using Hydraulic Briquetting Machine

How to use a hydraulic briqutting press?

Briquetting is a process that raw materials are compressed under high pressure to form round or square briquettes that can be used for heating purpose. If the raw material is wood waste or agro waste, the ligin content is liberated under high pressure, thus binding the materials into a briquette with high density. High temperature and high pressure are the key factors for briquetting. Briquetting often leads to a volume reduction of more than 10 times, which simplifies storage and transportation problems considerably.

-

Hydraulic briquette machine adopts hydraulic system to drive the briquetting process, which is distinguished from mechanical briquette press or screw briquetting press. This is called the biggest difference between them.

-

After being conveyed to the briquetting press, raw material will be fed into briquetting chamber through the distributing device installed above the chamber. If feeding volume goes insufficient, a detector placed on the feeding channel will transmit some signal to the feeder so that material input can be ensured in a constant way. Because insufficient input may adversely lead to decrease in yield and bad quality of briquettes.

-

Briquettes are formed within the hydraulic system with the features of stable performance, more stable and quiet than screw type briquetting press and mechanical stamping briquette machine.

-

Besides, the hydraulic system is equipped with cooling device to reduce high processing temperature.

-

The pressure value can be adjusted by handling the overflow valve. So the compression ratio will match with forming density of briquettes to deal with different kinds of raw material.

-

Complete intelligent liquid temperature control system. If the hydraulic oil temperature exceeds the top and bottom limitation of set temperature, the system will automatically start the cooling fan or electric heating system to guarantee oil temperature.

-

The quality and performance of the hydraulic briquette machine can meet EU standards.

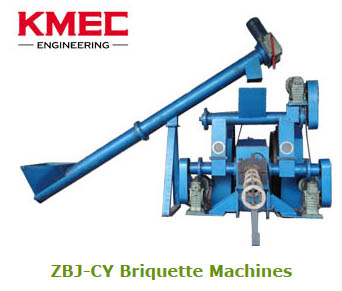

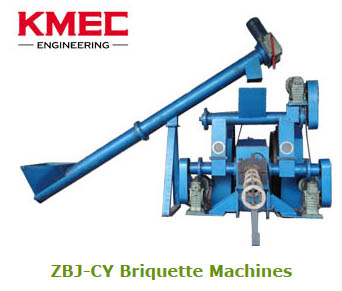

According to our experience, we suggest clients use hydraulic briquetting machine to produce briquettes in a relatively small scale. However, if you hope to install a briquette plant with larger production capacity, we would like to advise you to take mechanical stamping

briquette machine into consideration. KMEC is a professional briquette machine manufacturer with years of experience. We supply various of briquetting equipment ranging from small briquette machine to large briquette plant and production line. Customers all over the world are welcomed to contact us and purchase our products.

------------------------------------------------------------------------------------------------------------

Kingman briquettes making machine and biomass briquette machine will bring you a lucrative biomass briquette and charcoal fuel market. Hereby we can map out the prospect of using briquettes making machine and and biomass briquette machine.